Product introduction

Color-coated aluminum coils are the surface coating and coloring treatment of aluminum plates or aluminum coils. The commonly coated aluminum coils are fluorocarbon color-coated aluminum coils and polyester color-coated aluminum coils. They are widely used for Veneer, aluminum honeycomb panels, aluminum ceilings, roof surfaces, leftover material, cans, and electronic products. The performance of the color-coated aluminium coil is very stable, and not easy to corrode. Besides, the surface layer of the color-coated aluminum coil can achieve 50 years of quality assurance after special treatment. The weight of them per unit volume is the lightest among metal materials. Color-coated aluminum coils are currently the most popular new material.

Specification

|

Substrates: |

Aluminium (AA1100, 3003, 3004, 3105, 5006, 5052, 8011, etc), etc. |

|

Thickness: |

0.08-4.0mm |

|

Width: |

<1800mm |

|

Coils core diameter: |

150mm ,405mm, 505mm, 508mm, 510mm |

|

Coating thickness: |

PVDF >=25micron POLYESTER>=18micron |

|

Color standard: |

E < 2 or it is not obvious by eyeballing |

|

Pencil hardness: |

> 2HB |

|

Coating adhesive: |

not lower than first grade Impact: no any crack (50kg/cm, ASTMD-2794:1993) |

|

Bend stength: |

>100 times |

|

Boiling point: |

no any distortion and color change (in the 99 more or less 1 degree water, then cooling 2 hours) |

|

Corrosive: |

surface deep in the 5% muriatic acid and 5% NaCL, interior deepin the 2% muriatic acid and 2% NaCL, after 48 hours, no change |

Chemical Composition (For Reference)

Chemical Composition conforms to Chinese, American and European standard specification

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others: Each |

Others: Total |

Al:Min. |

| 1050 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | - | 0.05 | 0.03 | 0.03 | - | 99.50 |

| 1050A | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | - | 0.07 | 0.05 | 0.03 | - | 99.50 |

| 1100 | 0.95 Si + Fe | 0.05~0.20 | 0.05 | - | - | 0.10 | - | 0.05 | 0.15 | 99.0 | |

| 3003 | 0.60 | 0.70 | 0.05~0.20 | 1.0~1.5 | - | - | 0.10 | - | 0.05 | 0.15 | remainder |

| 3105 | 0.60 | 0.70 | 0.30 | 0.3~0.8 | 0.2~0.8 | 0.20 | 0.40 | 0.10 | 0.05 | 0.15 | remainder |

| 5005 | 0.30 | 0.70 | 0.20 | 0.20 | 0.5~1.1 | 0.1 | 0.25 | - | 0.05 | 0.15 | remainder |

| 5052 | 0.25 | 0.40 | 0.10 | 0.10 | 2.2~2.8 | 0.15~0.35 | 0.10 | - | 0.05 | 0.15 | remainder |

Alloy and Temper

| Alloy | Temper | Remarks |

| 1xxx: 1050, 1050A, 1100 | H42, H44, H46, H48 | ★Temper H12, H14, H16, H18, H22, H24, H32 and H34, for base material are provided as per client’s request and mutually agreed. |

| 3xxx: 3003, 3105 | ||

| 5xxx: 5005, 5052 |

Alloy Designation (For Reference)

Comparison of Alloy Designations for Aluminum Flat Products

| Alloy | Chinese Standard | American Standard | European Standard |

| 1xxx Series | 1050 | - | - |

| 1050A | - | EN AW-1050A | |

| 1100 | 1100 | - | |

| 3xxx Series | 3003 | 3003 | EN AW-3003 |

| 3105 | 3105 | EN AW-3105 | |

| 5xxx Series | 5005 | 5005 | EN AW-5005 |

| 5052 | 5052 | EN AW-5052 |

Temper Designation (For Reference)

| Temper | Definition |

| H42 H44 H46 H48 |

Strain Hardened and painted or lacquered, 1/4 Hard Strain Hardened and painted or lacquered, 1/2 Hard Strain Hardened and painted or lacquered, 3/4 Hard Strain Hardened and painted or lacquered, Full Hard |

| Temper H12, H14, H16, H18, H22, H24, H32 and H34, for base material are provided as per client’s request and mutually agreed. | |

Available Size Range:

| Dimension | Range |

| Thickness | 0.25 ~ 1.8 mm |

| Diameter | 500 ~ 1,550 mm |

| Length | Coiled, or 2,000 ~ 4,000 mm |

*Cut to length service is available for thickness over 0.5mm

Coating

| Paint | PE (Polyester), PVDF |

| Coating Thickness | Front side: ≥ 18 microns(PE), ≥25 microns(PVDF) Back side: 8~10 microns (PE or EP) |

| Coating Color | RAL colors, or by confirmed sample (customized) |

- Surface Protection: With PE/PVC film on main side (if specified)

- Gloss: 20% to 80%, depends on client’s requirement.

- Coil ID: 405mm, 505mm, 605mm

- Minimum Order Quantity: 5MT per size, total 20MT for one order

Application

Coated aluminum coil and sheet are more resistant to keep food fresh. Coated aluminum coil and sheet improves anticorrosive properties of aluminum, which are commonly used in food packaging, containers and cans. In addition, the application of coated aluminum coil and sheet embraces large industries including composite panel, ceiling, door, windows and electric appliances.

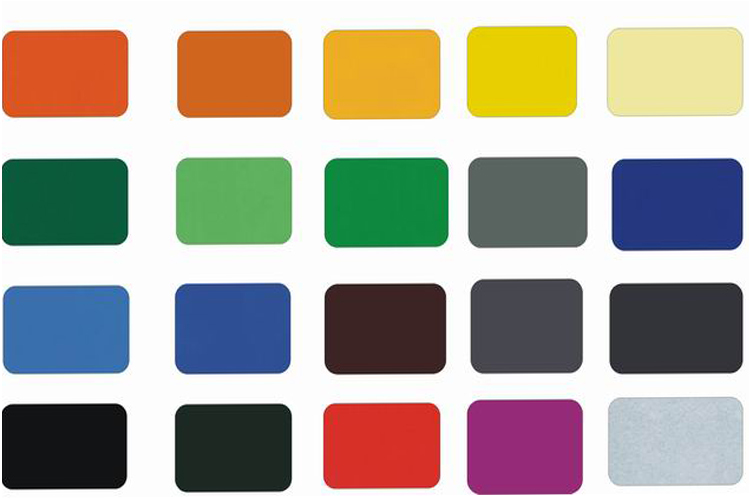

Color Chart

Color Match

1. For custom' color requests, we can deal as following:

A. Supply a physical sample of custom color. A color sample on metal is preferred. If other, it is also acceptable. But the color matching rate may be not good as color on metal.

B. New color sample is usually offered by our paint supplier in 5-7 days, special color should be in 7-10 days.

C. Upon receipt of color sample, please approve in writing as soon as possible. Once you approved, we will arrange purchasing and production.

Note: Color difference maybe occurred in different production batch, so it is suggested all panels are placed in one order for same project. And keep same direction as arrow on protective film when installing to avoid any color difference by vision.

2.For general colors, please refer to our color chart

Packing

Plastic film wrapped inside and carton packing. Wooden pallet with steel strip tied. Buyers can slao choose to pay for wooden case packing, which enables safer and more room saving in loading.